- About Us

- Lines

- Applications

- News

- Contacts

- Lingua

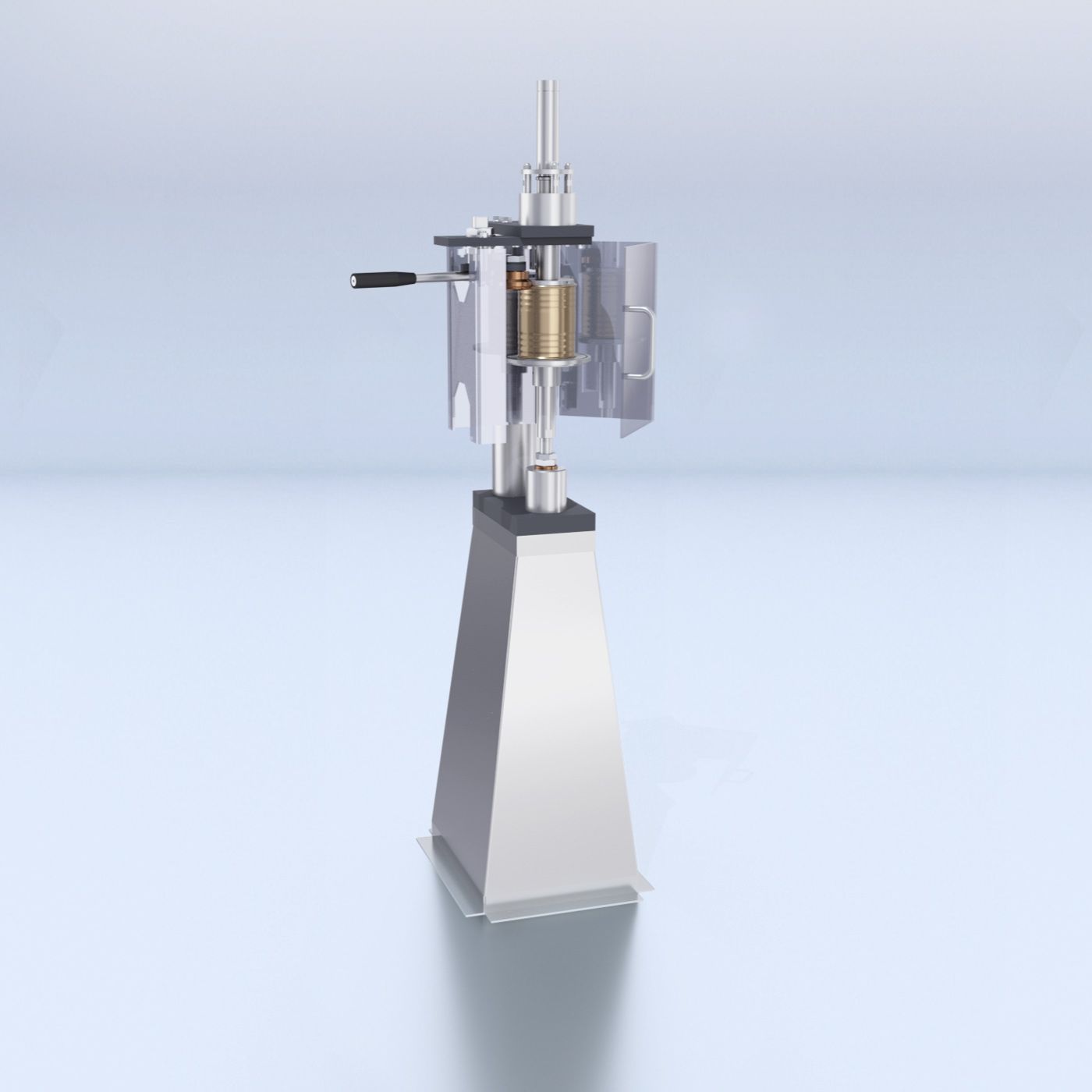

Tin cans seamer

MOD TFAGG-1

The machine performs the seaming of the cans size A2, A2½, A10 and A12.

The seaming process is performed in two steps:

The first step is the placement of the cover,

the second step consists of the seaming with rolls of first and second operation applied by a lever actuated by the operator.

The support plate for the cans is easily adjustable for the seaming of cans with different heights.

The rolls and the centring chuck are supplied according to the diameter of the can instead.

The machine is composed by:

– stainless steel support column

– stainless steel lower base

– pneumatic motor

– pneumatic system to lift the can up to the operating position

– transparent polycarbonate casing.

The machine is composed by:

– stainless steel support column

– stainless steel lower base

– pneumatic motor

– pneumatic system to lift the can up to the operating position

– transparent polycarbonate casing.

TECHNICAL DATA

| Type of package | A2 and A2½ CAN | A10 and A12 CAN |

|---|---|---|

| Capacity | Up to 500 pcs/h | Up to 250 pcs/h |

| Height | 1700 mm | |

| Width | 600 mm | |

| Length | 1000 mm | |

| Compressed Air consumption | 500 NL/min | |